Compliance with Chain-link Chainwire security fencing Australian standard AS1725.1-2010 is essential to guarantee the safety and structural integrity of security fencing installations. Chain-link fabric fencing, commonly is also recognised as chainwire fencing, chainmesh fencing, wire mesh fencing or Cyclone fencing. Protective Fencing ensure our project partners understand the intricacies of AS1725.1-2010.

Providing advice to specifiers such as engineers, architects, fencing installers, contractors and local government authorities. Within AS1725 there are two primary forms of chain link/ chainwire security fence grading, heavy-duty and light-duty, which delineate the wire specifications and applications suitable for different security needs. The heavy-duty variant, characterised by 3.15mm wire diameter, caters to high-security environments demanding higher longevity and robustness. Conversely, the light-duty option, featuring 2.50mm wire, finds its niche in lighter industrial applications. Beyond wire specifications, the selection of appropriate fence posts is critical. Classified into three distinct classes based on security requirements, each class mandates specific post types and grades. From corner posts to strainer posts, the choice of post grade and diameter is tailored to the security requirements of the installation.

Chainwire Fence – Security Grades

The two key forms of grading for Chainwire fencing as described in AS1725 (2010) are:

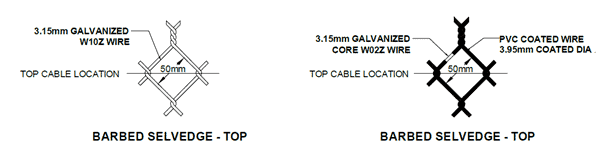

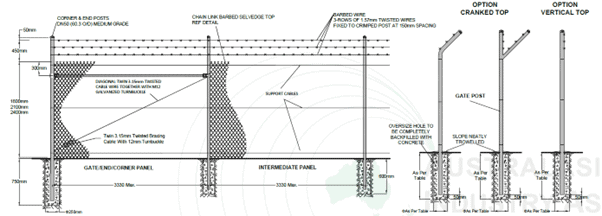

1. Heavy Duty chainwire security fence: 3.15mm wire for longer, durable service life in higher security applications. Heights commonly, 1800mm, 2100mm, 2400mm. 50mm Pitch/ mesh size. 3.15mm wire diameter. Pipe – Medium (Gate Posts and End Posts)

Heavy Duty Chainwire Fencing AS1725

Heavy Duty Chainwire Fencing AS1725

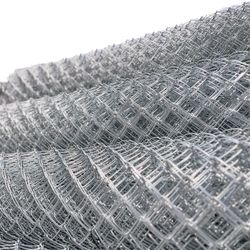

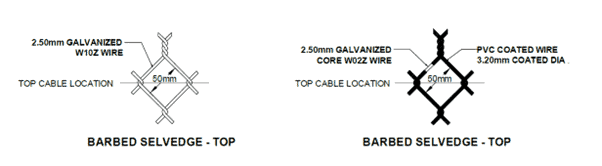

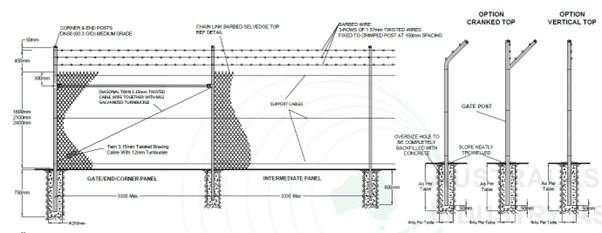

2. Light Duty chainwire security fence: 2.50mm wire and may be selected for light industrial applications where security and durability are a lower priority. Heights commonly, 1800mm, 2100mm, 2400mm. 50mm Pitch/ mesh size. 2.50mm wire diameter (Note light duty 2.5mm wire provides for only 60% of the load bearing capacity of heavy duty 3.15mm wire fabric). Pipe – Medium, Extra-Light

Light Duty Chainwire fencing AS1725

Light Duty Chainwire fencing AS1725

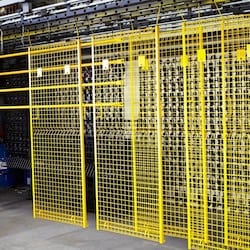

Chainwire Fencing is commonly used in transportation Rail infrastructure, Industrial, Tennis Court, Sports Court, Education, Construction, Mining, manufacturing, Defence, health, correctional facilities, power, utility, water and wastewater, aviation.

Chainwire Security Fences – How to select a Post Pipe Size

| Chainwire security fence Class | Chainwire Fence post* | Pipe Grades | Heavy Duty Chainwire security fence | Light Duty Chainwire security fence |

| Class 1 – Suit most Government departments and councils | Corner Post, End Post, Strainer Post, Intermediate post, Bracing Rail, Pipe Rails, Backstays | Medium – 100NB, 80NB, 50NB, 40NB, 32NB | Yes | Yes |

| Class 2 – Suit most industrial and commercial installations, long term security | Corner Post, End Post, Strainer Post, | Medium – 100NB, 80NB, 50NB | Yes | Yes |

| Intermediate post, Bracing Rail, Pipe Rails, Backstays | Light – 40NB, 32NB | Yes | Yes | |

| Class 3 – Suit most industrial and commercial installations short term security | Corner Post, End Post, Strainer Post. | Medium – 100NB, 80NB, 50NB | Yes | Yes |

| Intermediate post, Bracing Rail, Pipe Rails, Backstays | Extra Light – 40NB, 32NB | Yes | Yes |

*It is recommended to discuss your application needs with Protective Fencing.

- Intermediate post – strategically placed at consistent (Maximum 3300mm) intervals along the fence line, bridging the gap between corner and end posts. Their primary purpose is to provide support for the chain link chainwire mesh. Additionally, these posts can be extended above the height of the mesh to accommodate the attachment of barbed wire if required..

- End post – The boundary of the fence line, offering essential support for tensioning the chain link chainwire mesh. Typically, they are reinforced with bracing struts, stays, or top rails to ensure stability and proper tensioning of the mesh.

- Corner post – Facilitate changes in the direction of the chain link chainwire mesh along the fence line. Similar to end posts, they are commonly reinforced with bracing struts, back stays, or top rails to ensure structural integrity and support. Corner posts can also be used to support a chain link chainwire gate, should one be required.

- Strainer post – Serve as intermediate strainer points within a chain link chainwire fence, offering essential support for tensioning the chain link chainwire mesh. Strainer posts, much like other key posts, typically rely on additional reinforcement such as bracing stays, cable or top rails to ensure proper tensioning and structural stability

- Backstays or Stays – diagonal tubular steel member supporting post laterally and set into the ground.

- Bracing rail, top rails – Horizontal tabular compression member used in a braced panel.

- Baseplates – Metal plates welded to the base of the post to provide fitting and securing to concrete pavement or similar surfaces.

- Footings – Post footings are complex and many factors need to be considered when prescribing them.

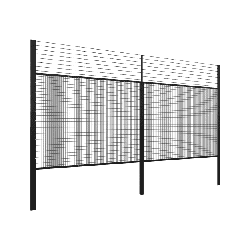

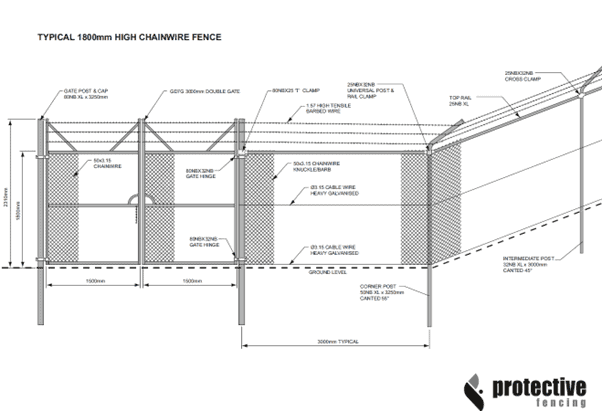

Drawing: Typical 1800mm High Chainwire security Fence – topped with 3 rows of barbed wire

Summary of Australian Standard AS1725-2010

The Australian Standard for Chain-link Fabric Fencing and Gates, Chain Wire Mesh “AS1725-2003 – Chain-link fabric security fences and gates” was updated in September 2010, with the new standard known as AS1725-2010 – Parts 1 to 5.

- Security for industrial, commercial and public buildings surrounded by open space (for example factory, office, school).

- Security for restriction of access to open spaces (Example, residential development, playing fields, open air storage, defence, airport, water storage, freeway, hazardous areas, quarries, mines.

- Security for government institutions and other areas to restrict access.

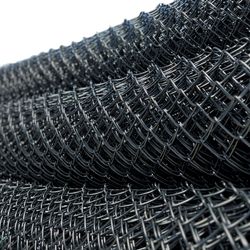

Tennis Court PVC Black chainwire mesh fencing

AS1725-2010 is the updated version of AS1725-2003. Key revisions encompass post size requirements, wire specifications, and permissible materials, ensuring enhanced durability and performance.

- DN50 Medium Grade (3.6mm wall thickness) galvanized pipe posts serve as the minimum size & type suitable for all Terminal posts, including End, Corner, and Gate posts.

- DN40 Medium, Light, or Extra-Light galvanized pipe posts, comprising the three DN40 pipe grades listed in AS1725-2010, can be specified as the minimum size for Intermediate posts.

- Chain-link fabric and associated wire, including Heavy Galvanized (HG) W10Z wire, Zinc/Aluminium-Alloy (ZA) W05Z5A wire, and PVC (Polyvinyl Chloride), Fuse bonded polymer-coated wire with a base metallic coating not less than W02Z, adhere to the standards.

- Chain-link fabric and associated wire made from Standard Galvanized (SG) W02Z wire fail to meet the minimum standard for any parts of AS1725-2010.

- The core wire diameter for chain-link fabric manufacture is either 2.50mm dia. for Light Duty or 3.15mm dia. for Heavy Duty.

- The maximum pitch (diamond) size for chain-link fabric stands at 50mm nominal pitch, measured diagonally across the diamond.

- Chain-link/chainwire Post spacing’s maximum post centres are 3330mm.

- Wire utilised for lacing wire must be 2.00mm core wire for all parts of AS1725-2010, whereas 1.57mm core Tie wire is exclusively for securing chain link fabric to horizontal cable wires.

While AS1725.1-2010 serves as the benchmark for chain-link security fencing in Australia, achieving compliance requires meticulous attention to detail. Protective Fencing assist stakeholders in navigating these standards, ensuring the deployment of fencing solutions that meet the highest quality and security benchmarks. The standard dictates stringent criteria for chain-link fabric and associated wire, mandating compliance with specified grades to meet the rigorous demands of security fencing. From galvanized wire to PVC-coated variants, adherence to prescribed standards guarantees structural integrity and longevity.

Our team understand that every project is different and therefore required a tailored response, that is why our team are dedicated to use our knowledge and leadership in understanding industry standards ensure that your project receives a bespoke fencing solution tailored to its unique requirements. Protective Fencing are proud of our involvement with Standards and committed to maintaining high standards for the industry, Australian Made supply of chain-link (chain mesh) security fencing.

The Australian Standard for Chainlink security fencing is AS1725-201, Parts 1-5

- Part 1 – 2010 Chain link fabric fencing – Security fencing & gates – General requirements

- Part 2 – 2010 Chain link fabric fencing – Tennis court fencing – Commercial

- Part 3 – 2010 Chain link fabric fencing – Tennis court fencing – Private/Residential

- Part 4 – 2010 Chain link fabric fencing – Cricket net fencing enclosures

- Part 5 – 2010 Chain link fabric fencing – Sports ground fencing – General requirements

We recommend utilising AS1725 in conjunction with AS 2423-2002 – Coated Steel Wire Fencing Products for Terrestrial, Aquatic and General Use Download your copy from Standards Australia, phone, email and by traditional mail order;

Web: https://store.standards.org.au/

Phone: 1800 035 822

International: +61 2 9237 6000

Email: success@standards.org.au

Post: GPO Box 476 Sydney NSW 2001 Australia

Chainwire Black PVC Sydney Rail corridor

Need some help?

Protective Fencing’s team of experts is here to provide you with the perfect chain-link / chainwire fencing materials solution tailored to your unique needs.

From deciphering the nuances of AS1725.1-2010 to selecting the ideal security grade and post types, Protective Fencing stands as your trusted partner, providing comprehensive support throughout the specification process. With their guidance, you can confidently navigate the complexities of chainwire fencing, ensuring the successful realisation of your project objectives with utmost efficiency and precision.

We design, manufacture, and deliver end-to-end solutions that complement our customers Chainwire fencing needs. We are committed to providing friendly customer service, focused attention to detail and fast turnaround and delivery times.

AUSTRALIA’S MOST TRUSTED FENCING SUPPLIER

Protective Fencing Australia has been delivering trusted, reliable and innovative security solutions since 1975. That’s why we’re Australia’s most trusted fencing partner.

CONTACT US

Email: sales@profence.com.au

Phone: 1300 436 200