⏱️ Estimated reading time: 3 minutes

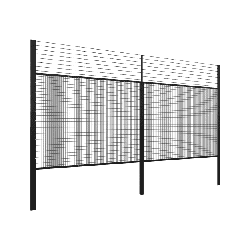

Australia’s fencing manufacturing industry is being transformed by advanced manufacturing technologies. As advanced manufacturing fencing continues to evolve, technologies like robotic welding, AI-driven design, 3D CAD modelling, CNC laser cutting, and integrated MRP/ERP systems are revolutionising the way fences are designed, produced, and delivered—boosting precision, reducing costs, and speeding up production times.

DID YOU KNOW? Advanced manufacturing can reduce fencing production time by up to 50%—without compromising on strength or quality.

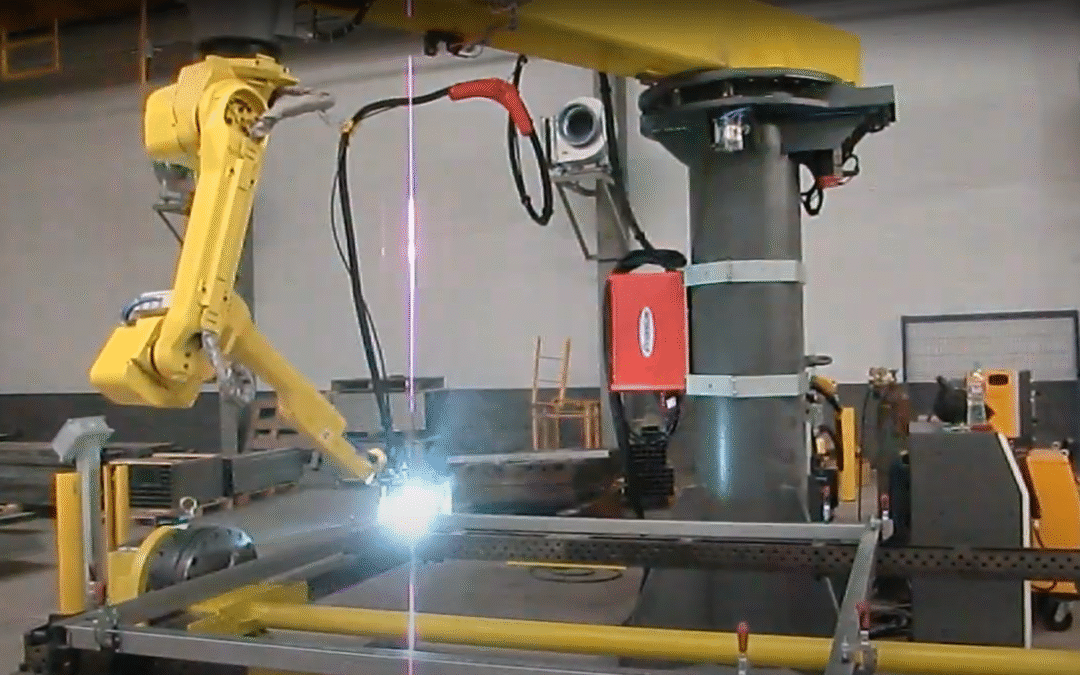

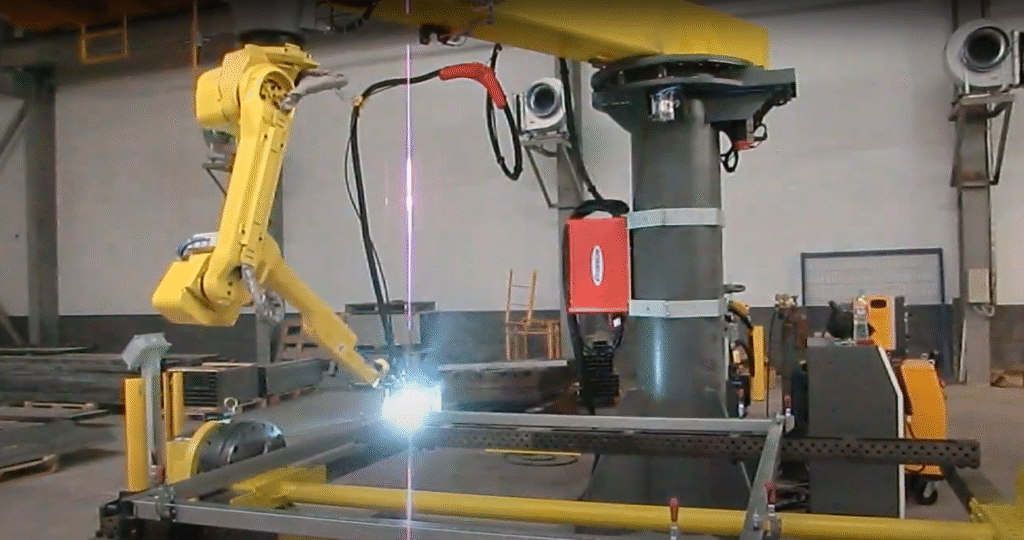

ROBOTIC WELDING: FASTER, CLEANER, SAFER

Robotic welding now plays a vital role in high-volume fencing production. Once programmed, robotic systems deliver exact, repeatable welds—eliminating human error and fatigue. In fencing, where repetitive joins are common, robotic welding boosts productivity, consistency, and workplace safety.

Key Benefits:

• Weld accuracies up to ±0.06mm

• Up to 3x faster than manual welding

• Fewer rework issues

• Safer, cleaner working environments

• Consistent quality across production lines

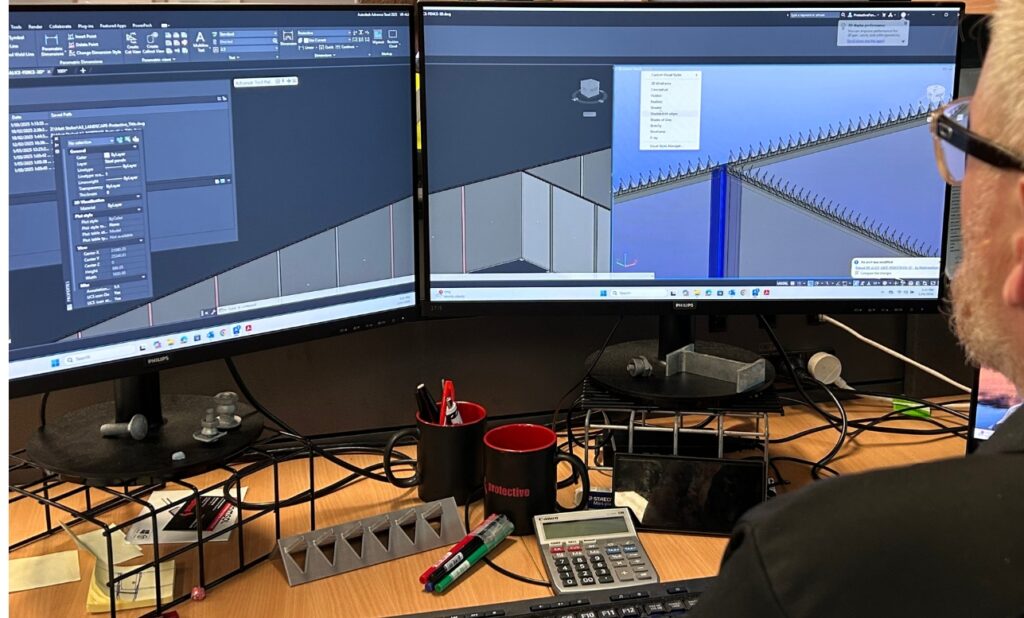

AI + 3D CAD: FROM IDEA TO INSTALLATION

Using AI-enhanced tools alongside 3D CAD, fencing manufacturers can simulate, test, and refine their designs before production begins. This reduces errors, improves material use, and helps transition more smoothly to production. AI also recommends design adjustments to optimise strength or reduce costs—adding measurable value before fabrication starts and enhancing the efficiency of advanced manufacturing fencing processes overall.

AUTOMATED BEAM LINES: SPEED MEETS PRECISION

Beamlines have redefined what’s possible in component processing. They can quickly cut detailed profiles into round, square, rectangular, or custom steel sections—without sacrificing precision. For manufacturers like Protective Fencing, this means faster turnaround and increased design flexibility.

Why it matters:

• Enables custom perforations, slots, and notches

• Optimises steel usage to minimise waste

• Streamlines production

INTEGRATED MRP & ERP SYSTEMS: SMARTER FROM THE INSIDE OUT

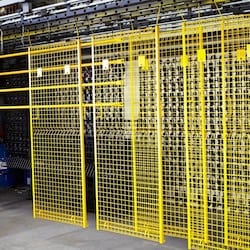

Advanced manufacturing relies on more than just hardware. Integrated Materials Resource Planning (MRP) and Enterprise Resource Planning (ERP) systems are now essential for managing quoting, inventory, production, dispatch, and delivery.

At Protective Fencing, our fully integrated MRP/ERP solution ensures a seamless experience—for both the business and the customer.

In Action:

• Real-time tracking of jobs and materials

• Faster quoting and accurate lead times

• Improved collaboration across departments

• Data-driven decision-making

• Streamlined order processing and customer response

THE BIG PICTURE: The Future of Advanced Manufacturing Fencing in Australia

The combination of robotic welding, AI, 3D CAD, laser cutting, and integrated digital systems is not just improving how we build fences—This level of automation is setting a new benchmark for advanced manufacturing fencing in Australia.

Technology isn’t optional anymore. It’s the standard. Forward-thinking Australian manufacturers are becoming faster, more agile, and better equipped to meet the evolving needs of today’s infrastructure and construction projects.

Bottom Line:

Advanced manufacturing isn’t just building fences—it’s building a smarter, stronger industry.

QUICK STATS AT A GLANCE

| Innovation | Benefit |

| Robotic Welding | 3x productivity, lower rework |

| 3D CAD + AI | Accurate, cost-effective design |

| CNC Laser Cutting | Fast, complex cutting with zero manual handling |

| MRP & ERP Systems | End-to-end integration and insight |

National Momentum in Advanced Manufacturing Fencing

The momentum behind advanced manufacturing fencing in Australia is being further accelerated by national policy. The Australian Government’s Future Made in Australia plan outlines a $22.7 billion commitment to revitalising sovereign manufacturing capabilities across key industries. This includes support for smarter systems, Industry 4.0 technologies, and innovation in sectors like fencing, infrastructure, and clean energy. These initiatives align with the direction Profence is taking—integrating automation, digital design, and ERP systems into every stage of our production.

To explore how government policy is shaping the future of our industry, read the full Advanced Manufacturing in Australia Report released by the Department of Industry, Science and Resources

Ready to spec smarter?? Contact us today about how Profence’s advanced manufacturing capabilities can support your next project — with faster lead times, precision-built systems, and full supply chain visibility.