⏱️ Estimated reading time: 5 minutes

Australian Made Fencing Matters, but 100% Australian is Essential!

“Australian Made Fencing,100% Australian.”

They’re phrases thrown around far too easily—seen in brochures, product blurbs, and sales calls. But in reality, Australian Made Fencing and 100% Australian aren’t just a marketing claim to us—they’re a line of defence between safety and disaster.

Unfortunately, across Australia, we’ve seen what happens when standards are ignored or sidestepped in the name of cost-cutting. From structural failures and public liability cases to tragic fatalities, the consequences are real—and often irreversible.

In industries like security fencing, where the product’s entire purpose is to protect people, assets, and infrastructure, meeting standards isn’t optional. It’s foundational.

This article explores why Australian Standards exist, what they’re designed to prevent, and why cutting corners on raw materials, compliance, or local certification isn’t just risky—it’s reckless. We’ll also explain the difference between Australian Made and 100% Australian, what true compliance looks like, and how you can spot the difference between stated and certified standards.

Why Australian Standards Exist

Australian Standards aren’t arbitrary checklists or red tape—they’re nationally agreed benchmarks for safety, quality, performance, and compliance. Developed by Standards Australia in consultation with industry experts, government, and regulators, these guidelines are created to prevent failure before it happens.

At present, the Australian fencing industry defers to British Standards for High Security Fencing. However, a dedicated Australian Standard Fencing is now in development. Once published, it will mark the first time we’ve had a complete, localised set of standards tailored to Australian conditions and expectations. These standards represent more than just specifications—they’re a promise that our infrastructure is built for Australian conditions, without compromise.

Why Standards Should Never Be Optional

When Standards are bypassed—whether through imported alternatives, cost-cutting, or shortcuts during installation—the consequences are often far more serious than a failed inspection.

They can be fatal.

Across Australia, numerous incidents have shown what can go wrong when standards and compliance codes are treated as optional. And while not every example is from the fencing industry, they all reinforce the same truth: minimum standards exist because people’s safety depends on them.

The Lacrosse and | Playground | Balcony Collapse |

|---|---|---|

Both buildings were clad in flammable imported materials that didn’t comply with fire safety standards. The result? Massive blazes, evacuations, and class actions involving millions of dollars.

| Between 2011 and 2020, the ACCC reported over 400 injuries linked to non-compliant playground equipment. Many of these incidents were traced back to suppliers or installers who didn’t follow required specifications—something we’re all too familiar with in the Australian Standards fencing space, where compliance is critical for safety

| Two women died and many more were injured when a balcony collapsed under the weight of partygoers. The coroner found serious construction failures and non-compliance with structural standards.

|

These are not isolated mistakes—they’re predictable outcomes of non-compliance.

In fencing, the same risks apply:

- A faulty anti-climb mesh can allow unauthorised access to high-security zones

- Compromised or damaged mesh can also lead to individuals escaping from secure facilities, posing serious safety and security risks.

- A rust-prone post system may fail under stress, putting people at risk

- A misaligned gate or weakened latch could cause injury on a school or construction site

And when something goes wrong? It’s not just the installer who’s held accountable—it’s everyone in the chain, from specifier to supplier.

Why Australian Made Fencing and 100% Australian Matter

When people think of critical safety infrastructure, they often picture fire systems, engineering tolerances, or structural load-bearing walls. But in reality, fencing plays just as crucial a role in protecting people and assets—especially when it comes to security, liability, and long-term durability.

A fence isn’t just a barrier. It’s often the first line of defence.

When standards aren’t followed in fencing projects, the risks are real—and they compound over time. Here’s what non-compliance often looks like on the ground:

- Welds that crack or fail under tension

- Anti-climb designs that don’t meet spacing or height regulations

- Gates that can’t self-close or fail under repeated use

- Imported components that don’t align with AS1725, AS4687 or site-specific requirements

And while many of these failures might seem minor at first, they often emerge after the job is signed off—when the cost of rectifying them is far greater.

For example:

- A failed industrial perimeter fence could allow break-ins, triggering large insurance issues.

- A non-compliant school gate could injure a child, leading to a negligence claim.

- A misaligned security mesh panel could void a facility’s compliance certification.

When the wrong product is chosen—or the right one isn’t installed to standard—the risk doesn’t just sit with the installer. It flows back to the project manager, the procurement officer, and the company that supplied it.

Australian Made Matters But – 100% Australian is Ultimate!

When purchasing any product, these days it means more than just supporting local jobs. It means choosing a supply chain that holds up the country!

As more suppliers join the Australian Made movement, we welcome the shift—it’s moving in the right direction—but the magic happens when manufacturers use Australian raw materials in the process.

While many products qualify for Australian Made certification, this doesn’t always mean the materials were sourced locally. At Protective Fencing, we take go deeper. Our materials are 100% Australian sourced — not just manufactured here — giving our clients full transparency, local quality, and peace of mind.

If you’re planning your next high-security or commercial fencing project

- Do you know where the steel came from?

- Do you know if the fabrication was done under local standards?

- Do you know the welds, fixings, and finishes are suited to Australian conditions?

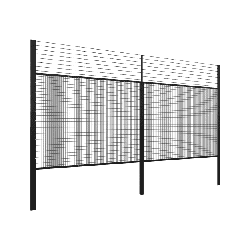

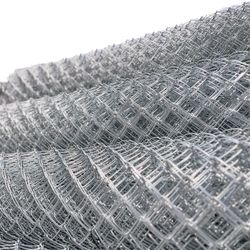

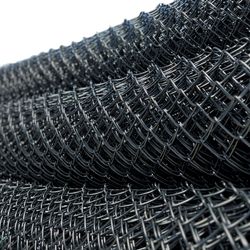

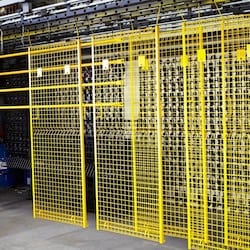

At Protective Fencing, we’ve built our reputation on certainty. Our PROMAX™ welded mesh, Steelmesh, Chainwire and Palisade fencing systems aren’t just Australian Made — they’re made from 100% Australian raw materials, built to Standard, and designed for Australian conditions and expectations.

Protective Fencing team manufacturing

We manufacture to meet the most widely used fencing codes, including:

- AS1725.1-2010 (Chainwire fencing for security and boundary use)

- AS/NZS 4687:2007 (Temporary fencing and hoardings)

- And other custom project specifications based on site risk, industry, and public use

We don’t believe in “close enough.” We believe in certified, compliant, and proven.

We welcome the new Fencing Australian Standards currently in development—after all, we live and breathe compliance.

Cutting Corners Isn’t a Cost Saver, It’s a Risk Multiplier

When lives, reputations, and infrastructure are on the line, compliance isn’t optional—it’s the minimum.

The problem is, in industries like fencing, the consequences of non-compliance often don’t surface until it’s too late. A gate fails. A mesh panel buckles. A rusted post gives way. And suddenly, the savings made by choosing a cheaper or uncertified product don’t look like savings at all.

Choosing Australian Made products that meet Australian Standards isn’t about ticking a box—it’s about protecting people. It’s about ensuring that the fence you install today won’t become tomorrow’s liability.

At Protective Fencing, we don’t just manufacture fencing. We build security, trust, and long-term performance—right here in Australia, for Australian projects.

Because in fencing, just like in every other industry – standards save lives.

That’s why Protective Fencing is proud to offer certified Australian fencing systems—from High Security 358 anti-climb mesh to chainwire and commercial-grade security solutions.

If you’re searching for a trusted fencing supplier in Australia, one that delivers compliant, certified, Australian Made AND using Australian Materials, we’d love to talk.